The curb and the equipment should be structurally capable of supporting intended loads and should be so designed that no penetration for drains power lines etc will occur through the roof flashing.

Roof dunnage details.

Watertight umbralla overlapping jack by minimum of 4.

Wall base termination detail.

Wall flashing with coated metal edge.

This introduction is intended to supplement the special notes on the individual construction details.

Heat welded walkway installation.

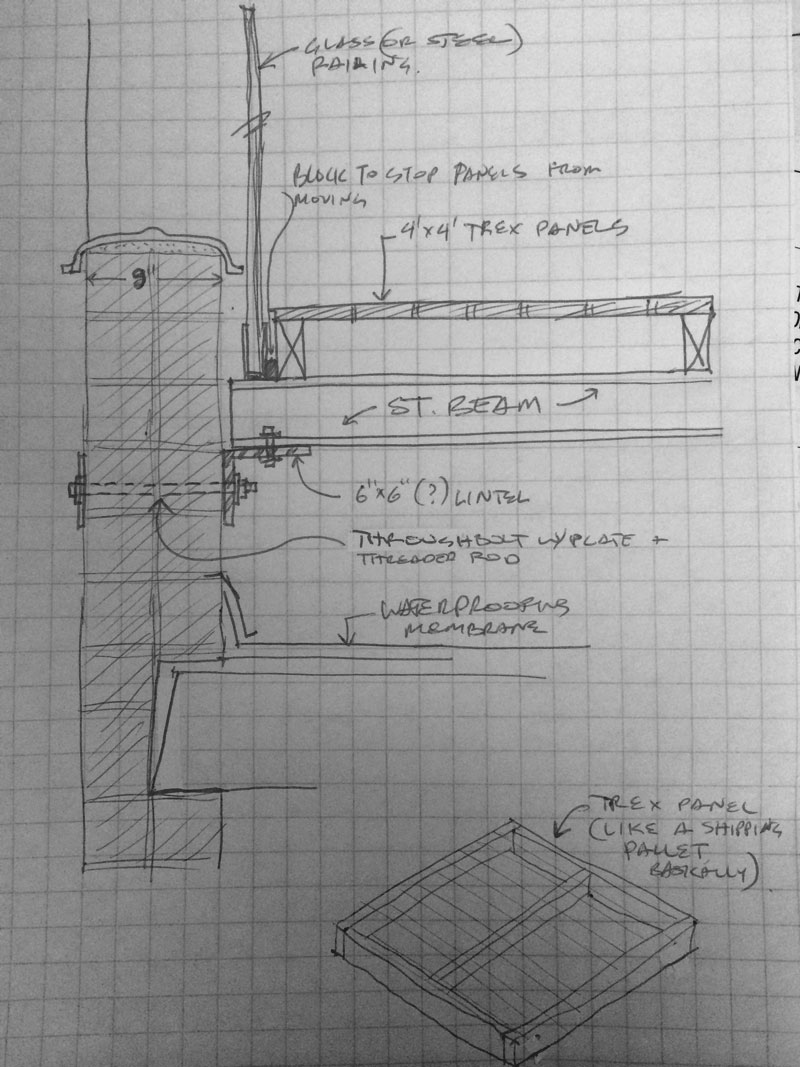

Dunnage platforms are designed for intermediate support between the equipment and rooftop steel.

Curb criteria for roof mounted equipment 1.

Elevated equipment supports sometimes referred to as dunnage supports provide a strong economical and adjustable roof support system for rooftop condenser units and mini split units.

The top of the curb should be level after installation.

When it comes to design we ve got the tools to get you from the desk to the roof.

Roof area divider curb type.

Fasten flange to wood nailer all sides prime flange before stripping.

Roof flashing details index fd01 interior roof drain detail fd02 interior drain with gravel stop detail fd03 scupper roof drain detail fd04 gutter roof drain detail fd05 roof top equipment curb detail fd06 roof top metal air shaft curb detail fd07 roof top wood air shaft curb detail fd08 roof skylight detail fd09 roof top chimney pipe detail.

Sheet metal roof jack minimum of 8 above roofing.

Paraguard expansion joint roof to wall with parasolo flashing.

One great advantage to a roof dunnage is the ability to avoid having to cut into the roof in order to add equipment on the top of the building through there are times when it becomes necessary.

Here you will find all of the epdm specifications 3 part specs details and installation guides.

Typically these are open steel structures located on the roof of a building consisting of steel beams supported on posts or bearing walls.

A roof dunnage provides strong support for equipment on the roof such as condenser units for an hvac system.

Dunnage platforms can be supplied galvanized or factory assembled with seismic isolators pre attached and provide continuous support underneath rooftop equipment.

Wall with self terminating parapro paraflex 531 liquid flashing.

Both the mini split roof support and condenser unit roof support are designed to allow airflow underneath and around the equipment that is being supported.

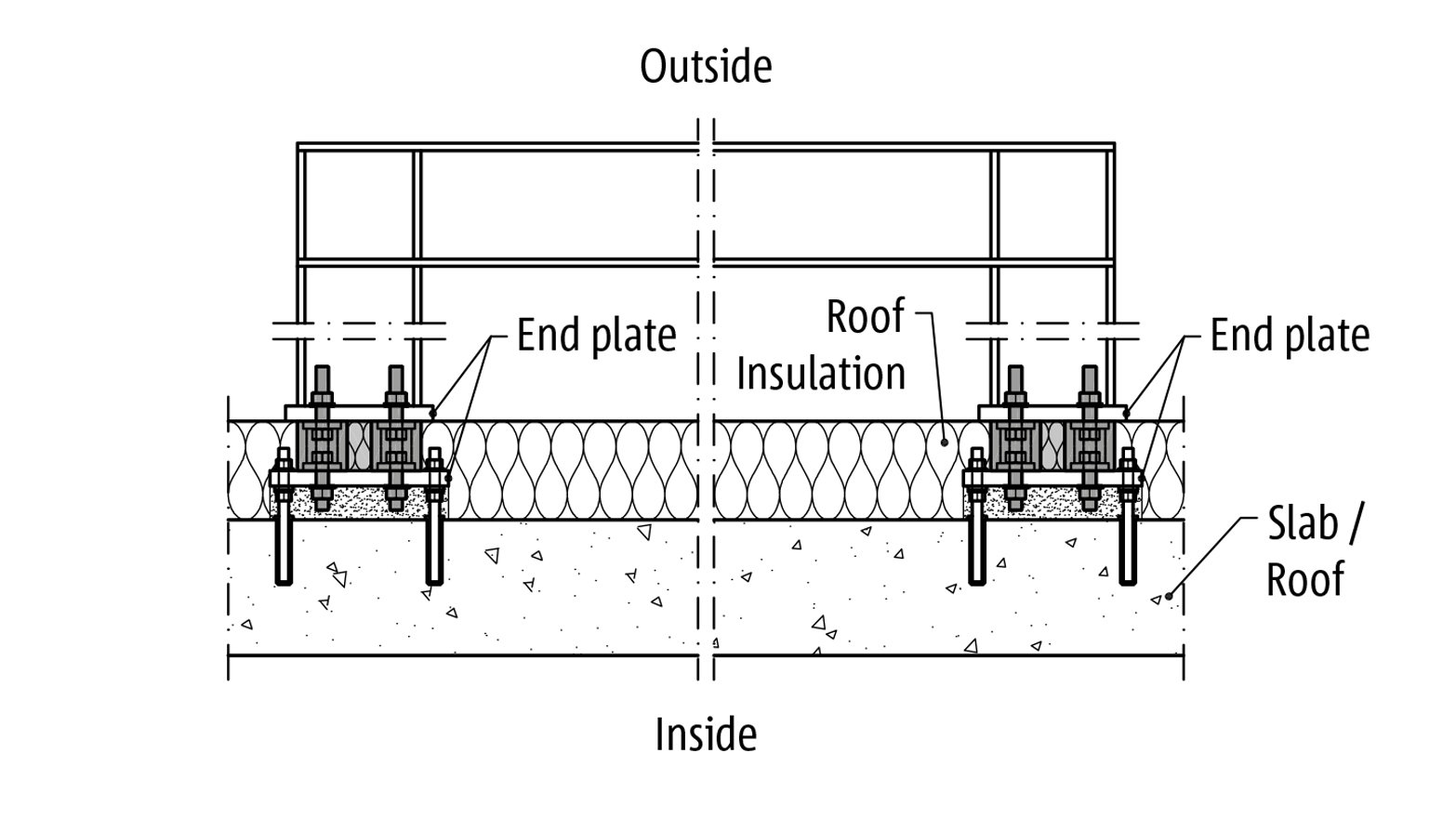

Figure 3 insulated steel deck frame width of equipment height above roof surfaces up to 24 14 25 to 36 18 37 to 48 24 49 to 60 30.

Dunnage can also refer to a structural platform for mechanical equipment.

Chapter 8 construction details provides technical information concerning the design and installation of construction details for quality spf roof systems.

Construction details are provided for the following spf roof system types.

If you have any questions when it comes to installation please contact our specifier services group for design and your local technical representative for the field.